What are the precautions for using an electric hoist with a steel wire rope?

Publication Time:

2022-11-14

Author:

Source:

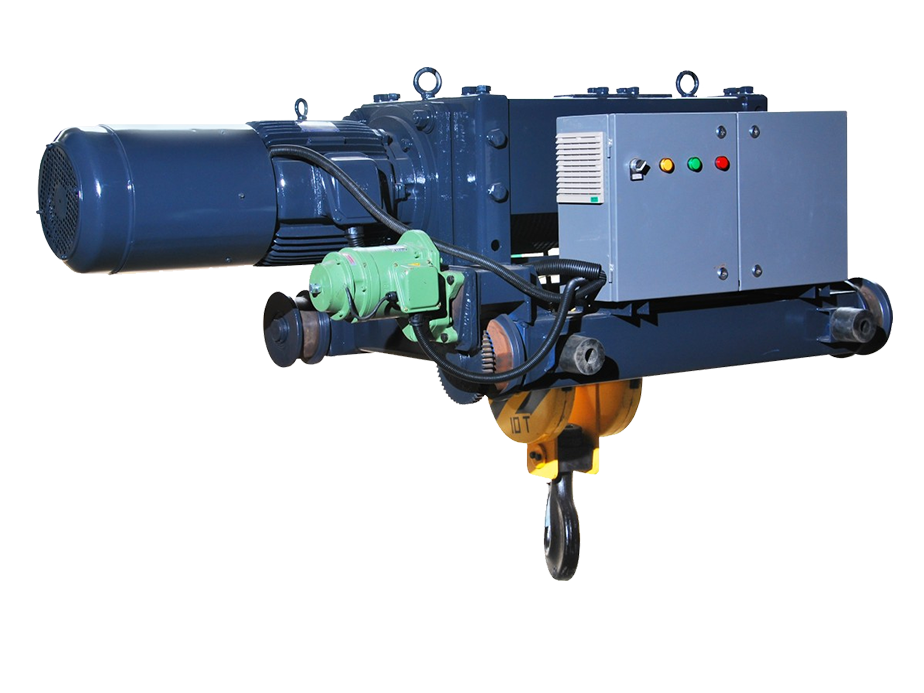

Electric wire rope hoist What are the precautions for use?

To operate the wire rope electric hoist well, we must pay attention to the following matters during operation:

1. Installation or reassembly Electric wire rope hoist should be run without load first. However, please ensure that the components are correctly installed and not energized.

2. Before normal operation, conduct a 10-minute static load test at 125% of the rated load at a height of approximately 100 mm from the ground to check for normal operation.

3. The dynamic load test is a test of repeated lifting and lateral movement under the rated load weight. After the test, check whether the mechanical transmission part, electrical part, and connection part are normal and reliable.

4. Between operations, it is forbidden to operate in an unauthorized environment or exceed the rated load and the rated number of shutdowns per hour (120 times).

5. During installation, debugging, and maintenance, the limit device should be strictly checked for flexibility and reliability. When the hook is lifted to the upper limit position, the distance between the hook shell and the drum shell should be greater than 50mm (10t, 16t, 20t should be greater than 120mm). When the hook is lowered to the lower limit position, ensure the safety ring of the wire rope on the drum, and the effective safety ring should be greater than 2 rings.

6. Do not press two manual switch buttons simultaneously to reverse the electric hoist.

7. After work, the power main switch should be turned on to cut off the power.

8. The electric hoist should be operated by a designated person, and the operator should master the safe operation procedures. Oblique pulling and lifting are strictly prohibited.

9. During the operation phase of the electric hoist, it should be regularly inspected by a designated person. If a fault is found, measures should be taken promptly and carefully recorded.

10. When adjusting the brake shoe of the electric hoist, ensure that the brake shoe S ≤ V/100 under the rated load (V is the distance of stable lifting within one minute under the load).

11. Scrapping standard of wire rope: The inspection and scrapping standard of wire rope should comply with CB/T5972-1986 "Practical Regulations for Inspection and Scrapping of Crane Wire Ropes".

12. During the operation phase of the electric hoist, sufficient lubricating oil should be maintained, and the lubricating oil should be kept clean, free of impurities and dirt.

13. When applying oil to the wire rope, a stiff brush or small wooden block should be used. It is strictly forbidden to apply oil to the working wire rope directly with your hands.

These are the operating precautions for this product. We hope that everyone can operate strictly according to the requirements.

Recommended News

Analysis of various application scenarios and advantages of electric hoists

2025-01-13

2025-01-02

2024-12-23