Do you know what working environments explosion-proof electric hoists are suitable for?

Publication Time:

2022-01-23

Author:

Source:

Speaking of explosion-proof electric hoists I think most people are confused. Let me give you a brief overview of the suitable work environments for explosion-proof electric hoists.

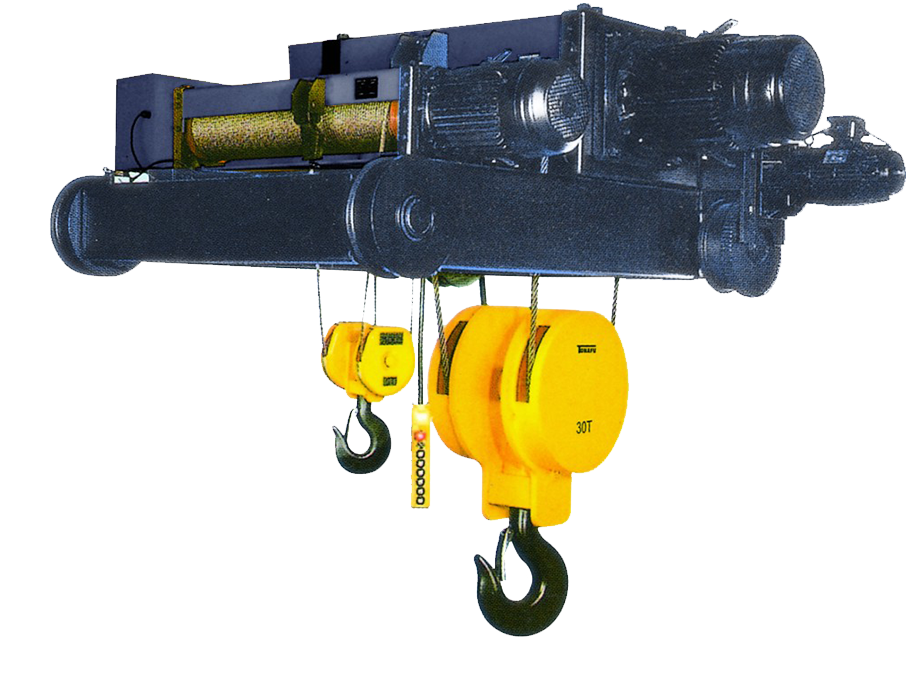

Anyone hearing the name explosion-proof electric hoist will realize it's different from a regular electric hoist. Simply put, it's a device that works in special environments and is an electric hoist type that can only be used under special circumstances. It consists of multiple separately detachable parts, making it very convenient to use and maintain, and can shorten the maintenance cycle. Moreover, its explosion-proof motor and explosion-proof control box also have separate explosion-proof structures. The control buttons, limit switches, and explosion-proof weight limiters also meet the corresponding explosion-proof requirements. Among many explosion-proof electric hoists, there are also grades, generally divided into three and four explosion-proof levels. Of course, the applicable scope is also different depending on the explosion-proof level.

Explosion-proof electric hoists are suitable for different levels of work conditions. Therefore, when used indoors, the temperature of the working environment must be maintained between 25 and 40 degrees Celsius. If used outdoors, protective devices must be added. So what exactly are these conditions? Suitable for Class I mining non-mining workplaces and Class II explosion-proof A, B, C grades, temperature groups T1-T4 groups of flammable gases or vapors and air-forming explosive gas mixtures. In addition, it is said that the shell and various parts of the explosion-proof electric hoist are also specially designed. In addition, the reducer of the explosion-proof electric hoist uses standard modular cylindrical gears, which is for easy maintenance. The parts of the explosion-proof electric hoist have strong universality and high interchangeability during use.

So, explosion-proof electric hoists what else needs to be paid attention to besides lubrication?

When using an explosion-proof electric hoist, if the lubrication work is not timely, many faults may occur during use, which will also have a great impact on our work. So, besides this, what else do we need to pay attention to? Let's find out together.

1. Pay attention to lubrication when using an explosion-proof electric hoist. Lubrication is very important, and the appropriate type of lubricating oil should be used. When lubricating the steel wire rope, pay attention to the heating temperature of the hemp core, which should not exceed 80 degrees Celsius.

2. Before formal use, please check the condition of the wedge, ensuring that it is firm and reliable, so that the probability of failure during use is much smaller.

3. Also, pay attention to not overusing it, and confirm that the power supply is normal before maintenance.

4. When using an explosion-proof electric hoist, pay attention to not lifting at an angle, and the object should be securely fastened. Pay attention to the object and prevent it from falling.

The above is a brief introduction to the suitable explosion-proof electric hoists working environments. I hope everyone can use the equipment better for work in the future. I hope everyone can use the equipment better for work in the future.

Recommended News

Analysis of various application scenarios and advantages of electric hoists

2025-01-13

2025-01-02

2024-12-23